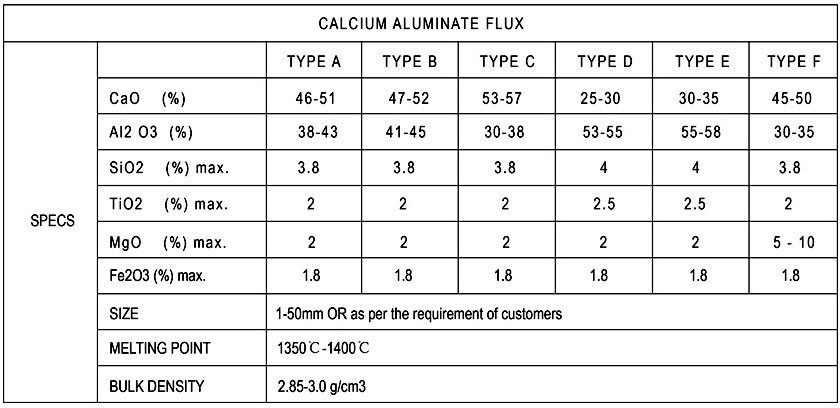

Name: Sintering Calcium Aluminate

Place of Origin: China

Supply Ability:

MOQ: 20MT

Port of Loading: Xingang China

Payment Terms:T/T, L/C, D/P

Introduction Products:

APPLICATIONS OFSINERINGCALCIUM ALUMINATE

A key feature for successful ladle metallurgy is slag control. Calcium Aluminate is specifically designed to have the required chemical composition and physical properties that make it easy to store and handle.

Calcium Aluminate is hard, stable and nearly dust-free.

The Calcium Aluminatehas good sulphur retention and performs effectively as a desulpheric slag.

Calcium Aluminate contains no fluorine compounds, thus avoiding refractory attack and atmospheric pollution. Calcium Aluminate is the best substitute for Calcium Fluoride.

Calcium Aluminate is an excellent cover slag for the prevention of gaseous pick-up from the atmosphere and is an effective fluid sink that absorbs inclusions from steel.

Using method

The amount should be according to practical application condition of different steels mills. We suggest that to add 5-12KG/Ton steel. Also it is can be added in twice: lay it on the bottom of ladle before tapping, second time is adding when in the ladle furnace. When the steel are stirring by argon blowing, the synthetic slag shall be efficiently improve the steel

Using feedback:

It is widely used in LF and VD. As the S content in steel not less than 0.03%,it should be low to 0.015% of S content after synthetic slag.

ADVANTAGE OF CALCIUM ALUMINATE

1.Consistent chemistry

2.Superior refractory protection

3.Readily available

4.Sized and packaged to customer specification

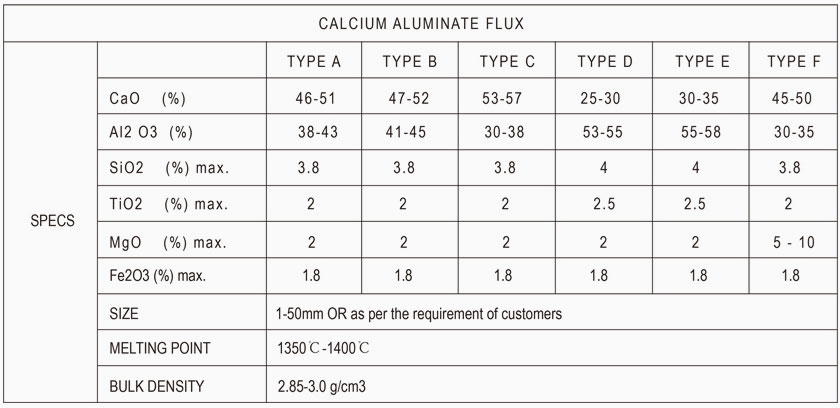

Name: Pre Melting Calcium Aluminate

Place of Origin: China

Supply Ability:

MOQ: 20MT

Port of Loading: Xingang China

Payment Terms: T/T, L/C, D/P

Introduction Products:

APPLICATIONS OF PREMELTINGCALCIUM ALUMINATE

Calcium Aluminate is a completely pre-meltingmaterials manufactured to meet the specific requirement of steel makers and metalluraists.

Ladle metallurgy and ladle furnaces are a critical quality control step between the primary melting furnace and the continuous caster. A key feature for successful ladle metallurgy is slag control. Calcium Aluminate is specifically designed to have the required chemical composition and physical properties that make it easy to store and handle.

Calcium Aluminate is hard, stable and nearly dust-free.

Calcium Aluminate melts readily at “steel-making” temperatures. The slag has good sulphur retention and performs effectively as a desulpheric slag.

Calcium Aluminate contains no fluorine compounds, thus avoiding refractory attack and atmospheric pollution. Calcium Aluminate is the best substitute for Calcium Fluoride.

Calcium Aluminate is an excellent cover slag for the prevention of gaseous pick-up from the atmosphere and is an effective fluid sink that absorbs inclusions from steel.

Using method

The amount should be according to practical application condition of different steels mills. We suggest that to add 5-12KG/Ton steel. Also it is can be added in twice: lay it on the bottom of ladle before tapping, second time is adding when in the ladle furnace. When the steel are stirring by argon blowing, the synthetic slag shall be efficiently improve the steel

Using feedback:

It is widely used in LF and VD. As the S content in steel not less than 0.03%,it should be low to 0.015% of S content after synthetic slag.

ADVANTAGE OF CALCIUM ALUMINATE

UNITED STEEL-MAKING PROCESSES

1.Consistent chemistry

2.Superior refractory protection

3.Readily available

4.Sized and packaged to customer specification

©Copyrigiht © WANPRICH METALLURGY D.O.O.2021